Importance of pH Testing for the Food Industry

pH testing has become one of the most essential measurements in the food industry. By making small changes to the pH levels, alterations can be done in food manufacturing. Every substance comes with a measurable level of acidity or alkalinity that is determined by the number of hydrogen (H) or hydroxyl (OH) ions. We all are aware of the basic definition of pH. It is the process of measuring the acidity or alkalinity of a specific solution. pH is commonly measured in the range of 0 to 14. pH 7 is neutral, values lower than 7 are acidic while those higher are alkaline.

The food pH scale enables the manufacturers in understanding precisely a particular ingredient’s reaction with the other. It also helps in determining how a product will fare in a specific environment. Below are a few of the points that highlight the importance of pH testing.

- Production of Food

The preparation of food is greatly influenced by the acidity of the food ingredient. As an example, wine aging and bread fermentation are greatly impacted by pH. The ratio of acidity/alkalinity plays an important role in determining the duration and speed of the reactions that are necessary for creating the required end product.

- Taste of Food

pH ratios change the flavors dramatically. In most cases, people would prefer having a bite that is from acidic food and beverages like dry wine. The pH level can also reduce the intensity of sour tastes. This same science is also applicable to processed food and dairy products.

- Texture of Food

Along with the taste, consumers also pay attention to the texture of the food sometimes even more than the taste. The way a product feels enables a consumer to judge a product. It is the texture that makes a person’s mouth water or cringe. The adjustments in pH result in alterations in the final product texture that influences the perception of enjoyment that a consumer feels. As an example, we can compare the creamy blue cheese with a crumbly aged Gouda.

- Appearance of Food

The physical appearance of the food is very important and people judge them by how they look. Veggies are the best example of food products that get judged mostly by how crisp and green they appear. The appearance that the product forms acts as a barometer for pH levels as they play a role in the texture and outer color. Food manufacturers have the ability to slow the change in color by tweaking the pH levels by utilizing specific ingredients and substances during preparation. Similarly, the pH changes can be stopped completely by using freezing techniques.

Food Safety is of the Highest Priority

Not just the surface features, pH levels play an important role in suggesting how long a particular food product is completely safe for consumption. With time, food products like fresh produce and dairy tend to lose their natural acidity. Eventually, the bacteria and balance tips are able to replicate. Timing plays a crucial role for food items that have added protection against bacterial growth along with preserving the quality of the food. Some food manufacturers add lemon juice or vinegar to dressings and mayonnaise to increase their shelf life and ensure the safety of the consumers. From the start to the finish, highly controlled and accurate pH measurements are pivotal for food safety.

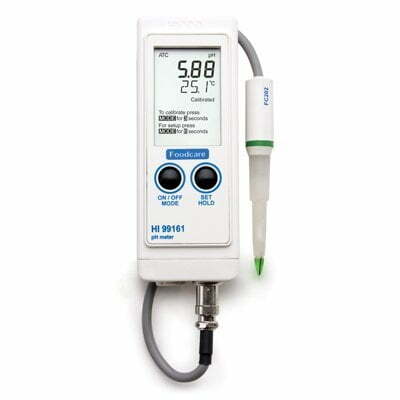

Get Accurate pH Measurements with High Quality Products from LABTEK Services

LABTEK Services is a premier provider of first-class laboratory supplies and impromptu technical support for the wide facilities that perform quality control for the dairy, food, and beverage industries within the UK. We are always there for you to deliver the best in class hygiene monitoring supplies from all over the world. LABTEK Services also provides technical support to various laboratories and supply chains within the industry.

Below are a few of the products that we offer:

The HI-98107 pHep® is a revolutionary product for the pH industry. This amazing product provides a simple and inexpensive solution to non-technical personnel for conducting accurate pH measurements. This is a pocket sized pH tester that is used by millions around the world for monitoring pH in industrial applications and laboratories.

The HI-981034 has a specialised conic tipped pH electrode that comes in a glass body. This specialised pH electrode is easy to clean and rugged. The HI-981034 has an open junction design consisting of a solid gel interface between the internal Ag/AgCl reference and sample.

This electrode is made with a food grade PVDF body and is perfect for use in the food industry, particularly with meat. The electrode is designed with a low temperature glass that includes a conical-shaped tip.